What is a Leaf Spring?

A Leaf Spring is an important suspension part which supports not only the vertical movement of the vehicle body, but also movement in various directions. It consists of mutilayered steel boards which, by optimizing the thickness and number of leaves, allows for stable, smooth driving and a comfortable ride, so is used in many vehicles such as trucks, trailers and buses.

The features of Leaf Springs made by Nakano Spring

Our leaf springs are made from high quality, fully tempered spring steel and manufactured in our own factory, being strictly monitored from form working, heat treatment, assembly, coating and up to final quality inspection. Visual inspection at each process is undertaken to maintain our high level of quality. Consistent high quality and level of engineering built up over the years is behind our ability to supply many OEM products as well as manufacture various types of leaf springs.

Types and features of leaf springs

Leaf Spring Types by Structure

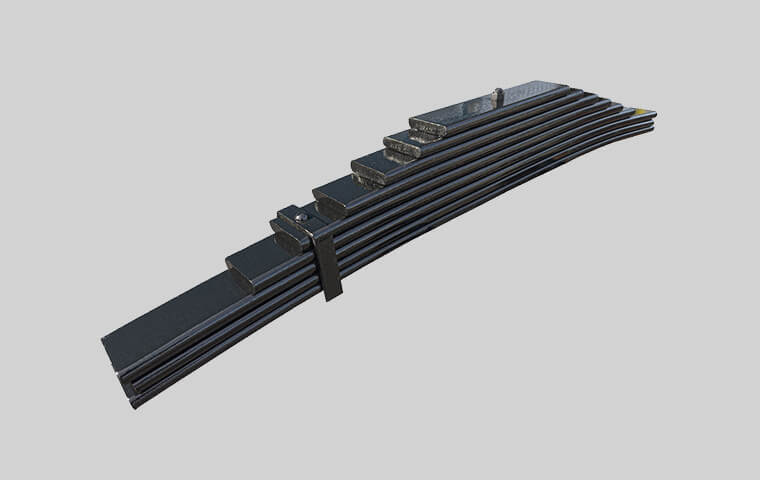

Multi Leaf Spring

(MLS)

A leaf spring is made by placing steel boards of different lengths one above the other. The required load rate and strength of the leaf spring is achieved by optimizing the thickness and length of the steel leaves. The ends may be tapered so that energy absorption efficiency is enhanced.

Long Taper Leaf Spring

(TLS)

A leaf spring with leaves rolled through most of its length so the thickness distribution throughout the leaf will result in a constant distortion rate when load is applied. This improves energy absorption rate which makes it possible to reduce the number of leaves resulting in lighter weight (compared to MLS). It also makes possible to create gaps between the leaves which helps prevent corrosion.

Difference Between Front and Rear Springs

Front Spring

(for front wheels)

On the front wheel, there are many directional forces at work, not only vertical but braking, stopping, steering, etc. and the multi-functional leaf spring supports it utilising the characteristics of the spring.

Rear Spring

(Double Leaf Spring, Rear Single Axle)

In a commercial vehicle, when comparing between an empty and fully loaded condition there is a significant difference in the load which the rear axle has to support, which affects the vehicle posture, cargo vibration, and steering stability. The leaf spring reduces the fluctuation this poses on the performance of the vehicle. The two springs are placed vertically and when the truck is empty only the lower spring is working and when load is added both springs work, with each load rate corresponding to the difference in load condition.

Rear Spring

(Trunnion Type, Rear Double Axle)

This is a trunnion suspension type of rear spring which is mainly used in large trucks with double rear axle. The center of the spring is connected to the truck body by a revolving support mechanism and load is transferred to the spring from both axles at the ends of the spring. When both rear axles are the drive axles, front/rear symmetrical springs are used so the load facter is the same for both axles. When only one of the rear axles is the drive axle, in order to secure ground grip and power on the drive axle side the spring is designed asymetrical to optimize load balance between the axles.

Product Line Up

Repair Parts for Trucks

Leaf Spring

We handle a wide range of repair leaf springs from those for small trucks to large trucks and trailers, from single leaf to spring assemblies, even manufacturer’s discontinued leaf springs. We can find them from our supply record of over 40,000 parts.

Repair Parts for Trailers

Leaf Spring

Our main items are for domestic trailers, but we also handle leaf springs for ocean container trailers and heavy equipment trailers. We sell single leaf springs as well as spring assemblies.

Simple Reinforcement Leaf Spring

(Extra Leaf – Additional Leaf)

Reduces front-up and unstable driving when fully loaded. Simple reinforcement spring with long history of usage, also available purpose made item which requires no cutting when attaching.

Springs for Land Cruiser

Land Cruiser, still very popular world wide. We have produced many types, in both domestic and overseas specifications.

Vibration Isolating Springs for Forging Machines

Springs placed under factory and office buildings which conduct forging. Absorbs vibration and reduces shaking of buildings. Leaf width of 70mm to 150mm available. Details can be discussed.

Springs for Railroad Trains

Springs produced for specialized railroad cars. Used in rail inspection cars and snowplow cars. Bolster springs have long been used in trams and cargo trains which face heavy vibration.