Production Line

Akishima Plant

Since its inauguration in 1964, it has strived for advancement in production technology and improvement of product quality.

Main Facilities

Shearing Machine

2 units 25T X 90B MAX

Eye Forming Machine (#1)

1 unit 16T x Φ60 MAX

Eye Forming Machine (#2)

1 unit 18T x Φ82 MAX

Taper Rolling Mill

2 units 18T x 250L MAX / 25T x 400L MAX

Heating and Quenching Equipment

1 unit Width 2.4m X Length 7m (2.5ton/hr) MAX

Tempering Furnace

1 unit Width 2.4m X Length 10m (1.5ton/hr) MAX

Shot Peening Machine

1 unit Projection Rate 520kg/min (@speed 80m/s)

Wet Bench Magnetic Particle Detector

1 unit AC/DC Magnetization, Axis/Coil Electrification, Horizontal Wet Type Device

Parabolic Rolling Mill

1 unit Width 100mm, Thickness 50mm, Rolling Length 2,500mm MAX

Camber Forming Machine

1 unit Width 100mm, Thickness 36mm, Leaf Length 2,000mm MAX

Stress Shot Peening Equipment

1 unit Width 100mm, Thickness 36mm, Leaf Length 2,000mm MAX

Administration Annex

Painting Factory

Production Facilities

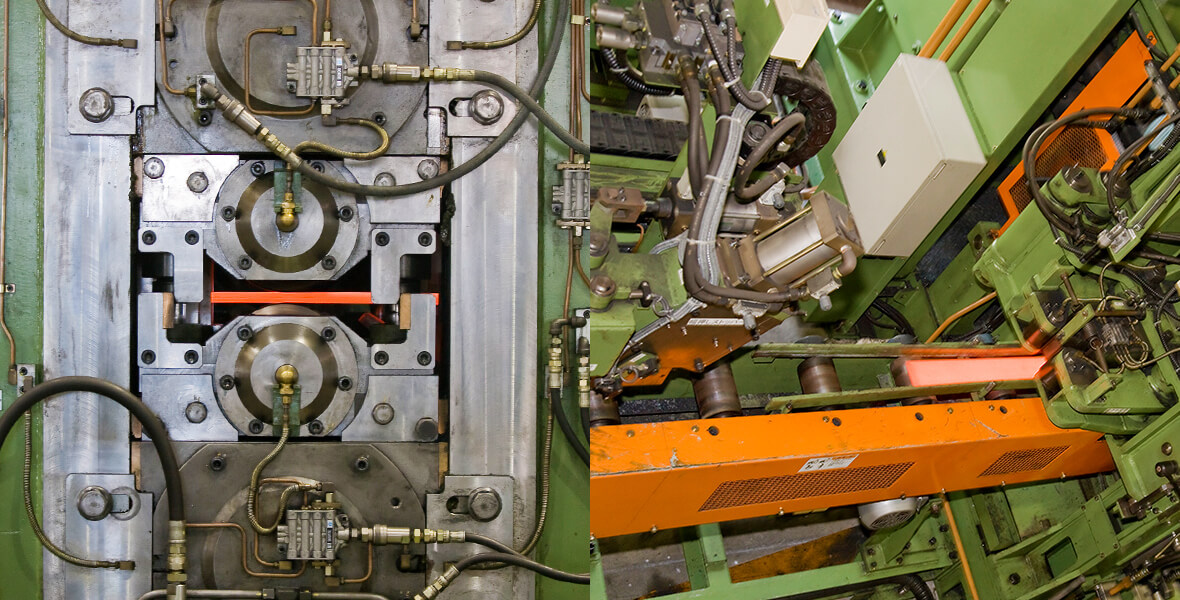

Control Board for Production Machines

Device for controlling Rolling Mill, Camber Forming Machine, Stress Shot Peening Machine, etc.

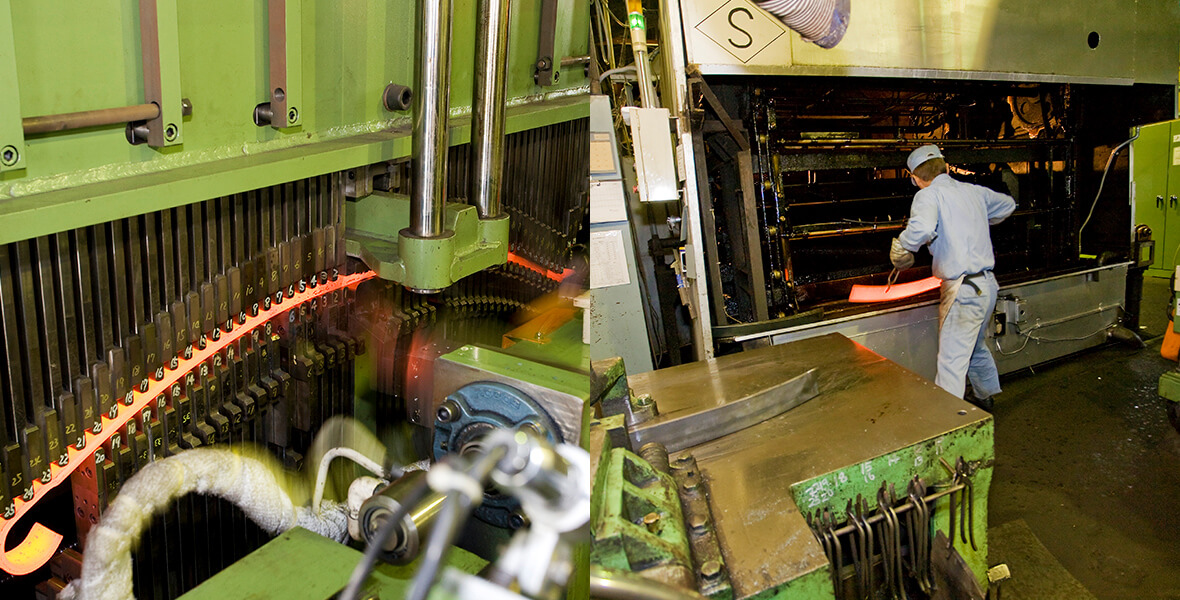

Rolling Mill

Computer controlled rolling operation

Camber Forming Machine & Heating and Quenching Equipment

Various shapes can be formed based on computer data

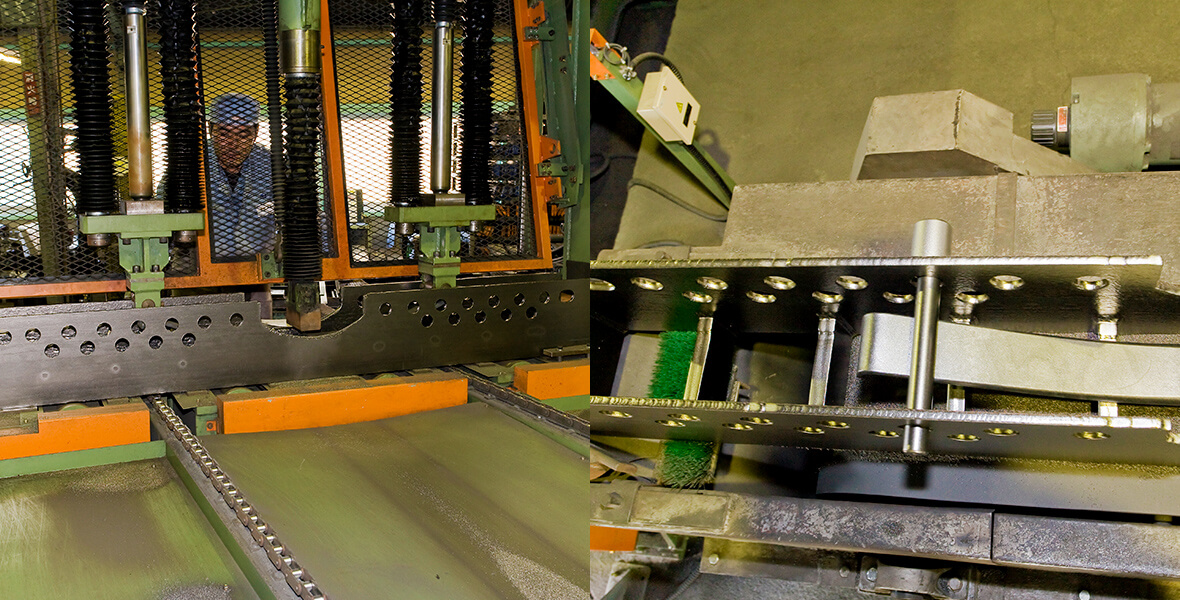

Stress Shot Peening Equipment

An indispensable process required to improve the durability of the spring